PSRU

Every experimental aircraft builder of the more advanced category, where a Propeller Speed Reduction Unit is required, will most likely end up with more questions than answers. Or in other words, as a responsible pilot of your aircraft, you should have questions, and also be rather critical to the many different vendors who are offering their more or less thoroughly prepared systems. Due to the fact that gears have been our main occupation and successful business since 1988, we have had a very keen eye on the different products on the market.

So, how difficult can it be, to make a reduction unit through two, or at the most, three gears, when an idler gear is incorporated in order to change direction? Well, we have concluded that it must be quite difficult, after having investigated the numerous accidents where a PSRU is involved.

EPI Inc.

Anyhow, we have found one vendor who has convinced us by their thorough and well founded solutions. The EPI Inc. is the only company to follow up their offer with a thorough explanation about how gears have been made through history, with examples from companies like Allison, Rolls Royce and Pratt & Whitney. Furthermore, you will find on their web pages, www.epi-eng.com, more than 130 pages with technical information which has been used by engineers and designers for many decades.

EPI Inc & Burhoe Machine Works

EPI also offers detailed information on torsional vibrations, fretting resonances and other dangerous side effects that you may experience when operating gears or other mechanical devices. Jack Kane, the founder and CEO of EPI Inc. also explains how to eliminate these problems, and designs PSRUs which incorporate both the idea of how to deal with the above mentioned effects, the technology and hardware to eliminate the same problems, and make your aircraft safer.

Business collaboration

We made a decision to contact EPI Inc, but also the owner of the Mark 15 project, Aron Burhoe, at Burhoe Machine Works. After three years of phone calls and emails, we became more than just business aquaintances, Mr. Kane and Mr. Burhoe became our good mentors, and friends, which is something we appreciate very much. Eventually this led to a business collaboration, and during early spring 2017, Aaron Burhoe, the CEO of Burhoe Machine Works, and Jack Kane, the owner of the EPI Inc, made a business agreement with Aerosport Engineering A/S. Aerosport Engineering A/S has the formal rights to produce, customize and sell the Mark 15 PSRU gear box worldwide.

Minor customizing work

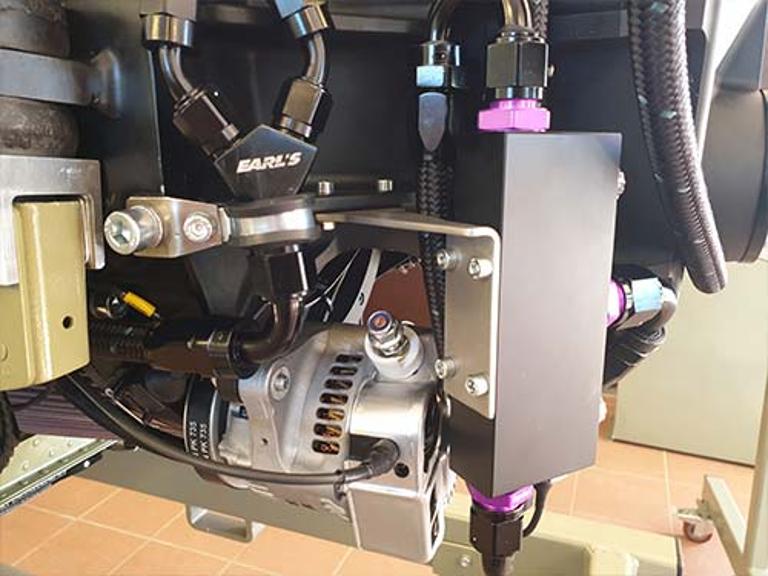

Aerosport Engineering has not made any changes to any internal design or components. We have made a new bellhousing in order to mount the PSRU directly onto the engine without any adapter. We have also incorporated a secondary alternator into the bellhousing. In addition, as mentioned under the chapter “Lubrication and oil system”, we are using one of the scavenge pumps to drain the excessive oil from the PSRU. We are also using a simple two valve system to switch between drain areas, according to flight attitude. It will drain from the bottom of the gear in normal flight attitude, and from the top of the PSRU in prolonged inverted flight.

The Mark 15 PSRU can handle loads of 1500 Hp, and the weight is only 38 kg/83 lbs. in a single mesh configuration, as you can see in the picture. The weight is without the bellhousing. The ratio can be customized fairly close to fit your needs, regarding engine power and propeller size. You can choose a design with an idler gear to have your prop run whichever way you prefer to fit your application.

The complete Mark 15 PSRU spread out in pieces before getting assembled. This is a single mesh PSRU, which means that the reduction unit contains only two gears, input shaft gear and propeller shaft gear, but no idler gear to change direction in this case.

The Bellhousing

The engine to gearbox adapter is a very essential part in order to be able to mount the PSRU to the engine. Normally these units serve several missions, which is the case in our set up as well. The first and the most obvious mission is to be able to mount the PSRU to the engine, since the engine and the PSRU do not have the ability to share the same bolting pattern, and also to be able to include the very important vibration absorption technology, which you will learn more about further down on this page. The second feature is that it has it has mounting flanges machined on both sides so that engine/gearbox vibration mounts can be attached.

Redundancy Alternator

The third feature, and maybe not so commonly seen, is that we have, with the help of Jack Kane at EPI Inc, been able to incorporate a second alternator attached to the bellhousing, using it's own set of pulleys and a multi rib belt. This particular belt does not have any other mission but driving the alternator. For your information, there is another alternator mounted in the other end of the engine, where the multi rib belt runs both the alternator and the water pump. For redundancy reasons, we found it important to drive the alternators from two different sources. For example, if one of the multi rib belts fail, we are loosing only one alternator. In the first picture you can also see the “cut out hole” for the governor on the side of the unit. In picture two in this section, you can see that the bellhousing has some convenient spots where you can mount other features also, like this small valve body controlling PSRU return oil. The complete bellhousing, or adapter unit, is machined out from a piece of 7075 aluminum alloy and is very sturdy with an average wall thickness of 8 mm/0,315 Inch, and with a weight of only 10 Kg / 22 Lb.

PSRU features

We would like to show you some of the features of the Mark 15 PSRU, and that means we have to go a little deeper in details.

First of all, EPI gearboxes use hydrodynamic fluid-film bearings (just like the crankshaft bearings in your engine) for the propeller shaft and the drive-gear. These bearings have far greater capacity than rolling-element bearings of the same size, and are much lighter and physically smaller than rolling element bearings which could carry the large loads required. In addition, the thrust-handling capacity of ball bearings (which some PSRU's use for their propshaft) is extremely limited.

The vertical offset between the crankshaft centerline and the prop centerline is 200.66 mm or 7.90 inches.

The available ratios

The available ratios are: 1.724, 1.821, 1.926, 2.038, 2.160, 2.292, 2.435, 2.478, 2.591, 2.762, 2.950, and 3.158.

It can provide either direction of prop rotation with either direction of engine rotation. This can be done by adding an idler gear to the unit. The gear housings, front and rear, will obviously be different to be able to incorporate another gear to change direction of the propeller shaft. This is now what we call a two mesh gear box.

The input torque capacity exceeds 1600 lb-ft. (depending on the required safety-margin).

The propeller thrust capacity (all configurations) is 3000 lbs. in either direction (pusher or tractor applications).

The propeller flange conforms to SAE ARP-880, which is the 8-bolt, 2-dowel configuration used on the P&W PT-6 and Garrett TPE-331 turbine engines, and most Continental GTSIO-520 engines;

The minimum length from engine to prop flange is 14 inches. It is available with extended propshafts to move the propeller further away from the engine to assist with specific cowling issues.

The integrated controllable propeller system is the common single-acting hydraulic configuration (Hartzell, McCauley, AeroComposite, MT, Hoffmann, etc.) found in most piston-engined aircraft.

The propeller governor drive is integrated into the gearbox and provides an AND-20010 governor mounting pad, vibration-isolated gear-drive, and internal propeller control plumbing.

The Mark-15 includes provisions for a reversing prop and the PT-6-style beta-feedback mechanism for the control of a reversing prop.

The lightest version (single-mesh) weighs close to 38 kg/84 pounds, with the governor attached. Bellhousing is adding 10 kg/22 Lb. (NOTE: weight varies with ratio, torque capacity and direction of prop rotation).

In addition to fit onto our ASE-650 Saga (BMW M73 B54 block), the Mark-15 has provisions to fit these popular engines: Smallblock and Bigblock Chevrolet, GM-LS, Ford Windsor, Chrysler Hemi, Jaguar-V12, and the Falconer V12.

Lubrication

The Mark-15 uses engine oil for lubrication, cooling and propeller control, so it requires no additional heat exchangers, which helps to reduce cooling drag.

The Mark-15 also contains several gearbox "health-monitoring" features, including (1) a chip detector, (2) two temperature sensors (for incoming and exiting oil) and (3) an oil pressure sensor location. The temperature sensor for the returning oil is located in the housing of a simple two valve system to switch between drain areas, according to flight attitude. It will drain from the bottom of the gear in normal flight attitude, and from the top of the PSRU in prolonged inverted flight.